How We Manage Consumables at CARS24 Hubs

Imagine walking into your neighbourhood CARS24 hub, ready for a cup of hot tea and a quick car-cleaning spray before you browse our latest pre-owned vehicles. You expect everything from sugar sachets to coffee cups to be right where it should be. Sounds like a small task but actually, a lot goes on behind the scenes: maintaining 77 different consumables across all the hubs is no small feat. Also, maintaining quality is of great essence.

So, here’s how we’ve turned this daily challenge into a smooth (almost invisible) operation, making the most of technology at our disposal.

1. From paper to pixels (digital checklists)

Gone are the days of handwritten logs and guessing games. Every morning, our hub managers fill out a simple online checklist (example: “tea bags: 12 boxes,” “Car-wash liquid: 8 bottles,” and so on) and this real-time data zips straight to our central system, giving us instant visibility into what’s on each shelf. At any given point of time.

2. Knowing what “Enough” really means

Turns out not every hub uses the same amount of sugar or cleaning fluid. To decide the “just right” amount, we calculate two key metrics for each item:

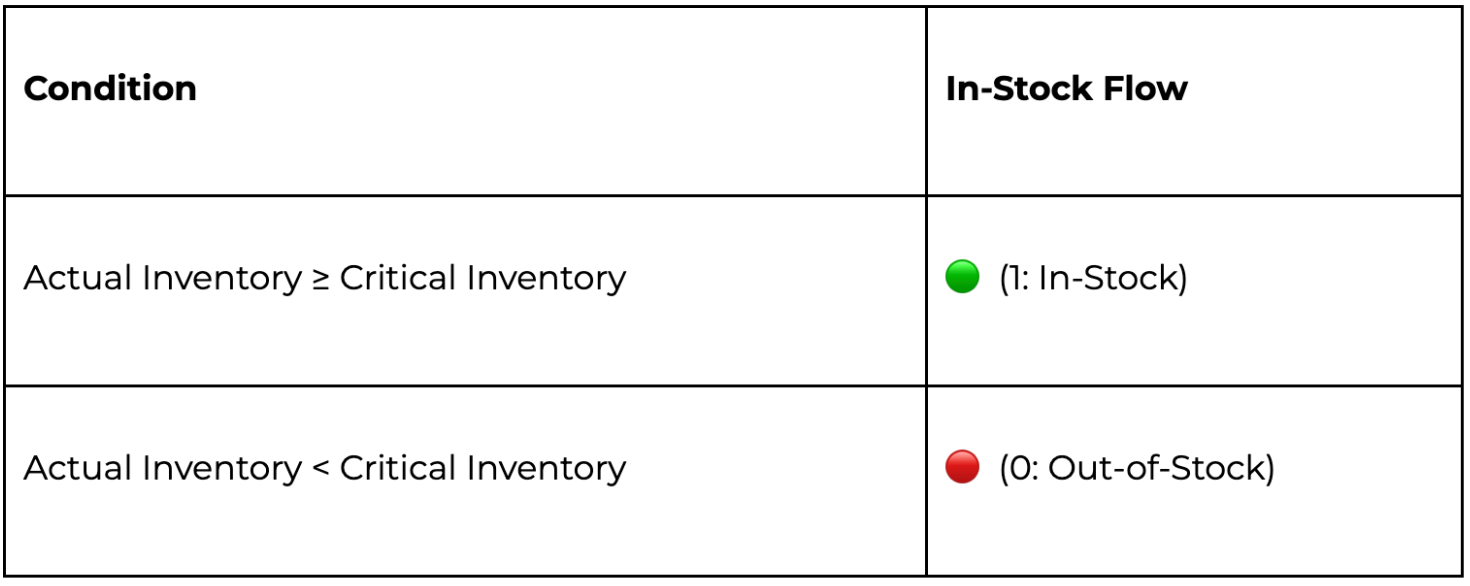

- In-Stock Flow: A traffic-light indicator showing if a hub has at least its critical inventory (green indicator = in-stock; red indicator = out-of-stock).

- In-Stock Volume: The exact percentage by which a particular product is less or more than the critical inventory. (Critical inventory 50 units, actual inventory 40 units; means in-stock flow is zero and in-stock volume is 80%).

3. How critical inventory is calculated

The secret to never running out isn't just keeping lots of stock; it’s keeping the right amount for each item at each hub. Critical inventory is our safety cushion, calculated using:

- Lead time: How long it takes to get a fresh delivery from our supplier.

- Variability in lead time and demand: Because sometimes deliveries (or consumption) speed up or slow down unpredictably.

Critical Inventory=(Average Daily Usage×Lead Time)+[Z×Standard Deviation of Lead Time Demand]

Where:

- Average Daily Usage x Lead Time covers stock needed during replenishment lead time.

- Z x Standard Deviation adds a buffer for variability, with Z based on desired service level (e.g., 1.65 for 95%).

4. A friendly traffic light for stock

Once we know each hub’s on-hand count and the critical level, we assign:

5. Calculating the “Refill Amount”

When a hub turns red, we calculate exactly how many units to send:

In-Stock Volume=Critical Inventory−Actual Inventory

In-Stock Volume=Critical Inventory−Actual Inventory

This ensures our next delivery or transfer fills the gap—no more, no less.

6. Smart stock swaps: Inter-hub transfers

Sometimes one hub has extra stock while another is running low. By comparing in-stock flow and volume across items, our system flags transfer opportunities allowing quick and cost-effective inter-hub stock movements.

7. See the system in action

Here’s a real dashboard from August 2, 2025, showing how our inventory flows look across hubs, cities, and hubs:

This comprehensive view instantly highlights:

- Our overall in-stock flow (85.7%), meaning most items in most hubs are above their critical level.

- Top performing cities and hubs, as well as those that need attention.

- Easy follow-up for targeted support, restock, or inter-hub transfer.

And here's the real milestone: Just three weeks ago, our in-stock flow across hubs was at only 27%. Thanks to this disciplined approach and the dedication of our hub teams, we’ve climbed rapidly to 85.7% today. That’s progress you can feel at every visit!

8. A small daily step with big impact

Our entire system’s success hinges on one simple but vital action: hub managers sincerely filling out the daily checklist every morning. Accurate and timely updates ensure real-time inventory data stays reliable, keeping stock flowing smoothly and customers happy.

9. Why it works and why you never notice

- Fewer Surprises: Stockouts (no cups for your coffee!) become almost extinct.

- Happy Teams: hub managers and city heads spend less time chasing supplies and more time serving customers.

- Lean Operations: We avoid overstocking, meaning less tied-up capital.

Next time you step into a CARS24 hub for that complimentary tea or quick spray-down, remember there’s a simple, data-driven ballet making it all possible. From an online checklist to precise inter-hub stock swaps, we’ve built a system that keeps every hub stocked so that you can focus on finding your perfect ride back home.

Loved this article?

Hit the like button

Share this article

Spread the knowledge

More from the world of CARS24

CarInfo is now part of CARS24

We have always believed in simplifying car ownership and together we can make it a 100x better experience for vehicle owners.

Our City Is Choking Our Families

Delhi does not need awareness, it needs discipline. We need a government that’s willing to be disliked for the right reasons and citizens willing to be disrupted.

Best Job Opening in the UAE

As the market evolves, we expect this way of thinking to become standard and this policy to be extremely ordinary. Quality and accountability always find their way to each other.